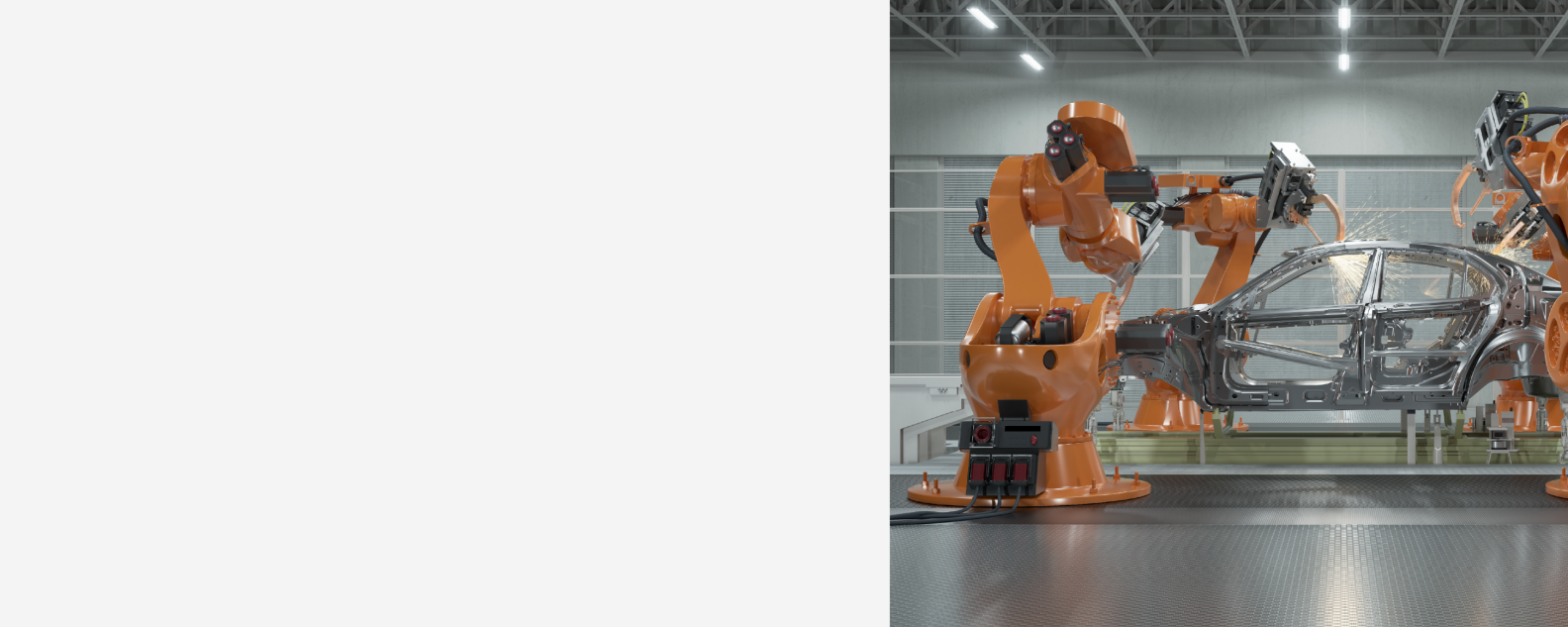

Automakers are awash in data, growing at orders of magnitude. New product features, software updates and autonomous testing call for data governance initiatives across the automotive sector from car manufacturers’ engineering and production to customer service.

Partnering with IBM helps automakers and automobile manufacturers modernize at their pace, using existing automotive manufacturing infrastructure already present in the automobile industry. By enlisting IBM AI, automation, hybrid cloud and Zero Trust technologies, automotive companies can build a faster, smarter, more secure and agile business.

Red Hat and General Motors collaborate to advance technology for software-defined vehicle manufacturing at the edge.

Weave together data from anywhere and apply AI at the edge to empower predictive decision-making

Make roles more productive with intelligent workflows that enable people to achieve higher value outcomes, faster

Achieve improved product quality, equipment uptime, asset life and worker safety with intelligent asset performance management

Transform security from point solutions to an end-to-end, cross platform approach that maintains the integrity of your value chain and protects your connected products, cloud and edge ecosystems

Red Hat and General Motors collaborate on a functional safety certified in-vehicle Operating System.

Continental achieves faster and more flexible data storage to train AI models

Toyota focuses on zero downtime and zero defects to keep the line moving

Andritz protects industrial plants, equipment, software and people from cyber threats

Celestica navigates ESG data collection and reporting for an industrial business